The MF Fuel Pump is constructed of out of billet aluminum. Internal hardened gears are hand lapped increase lifespan and reduce the coefficient of friction. The gear housing is constructed from Anti-Galling and corrosion resistant material and further DLC coated to resist the low lubricant properties of alcohol based fuels.

Its small size and weight can supply huge amounts of fuel. The Magnus MF Mechanical fuel pump supports up to:

9.7 GPM @ 40 psi relative pressure @ 80% IDC at 5000 RPM of pump speed (1/2 engine speed) 2800HP on Methanol 4300HP on Ethanol 5700HP on Gas

8.5 GPM @ 60 psi relative pressure @ 80% IDC at 5000 RPM of pump speed (1/2 engine speed) 2500HP on Methanol 3700HP on Ethanol 5000HP on Gas

- 3/8″ Hex Drive

- 1/2″ Belt Drive with .125″ Keyed

- 3/8″ Hex Drive

- 1/2″ Belt Drive with .125″ Keyed

- Magnus Pumps use very tight tolerances, to ensure safe operation you MUST use pre and post fuel filters.

Direction of Rotation :

- Many people use them on street cars, they will usually retain the prime for 1 week. As long as you run a pre filter (40 micron) to protect the pump and a post filter (10 micron) to protect your injectors

- Do not run dry for any amount of time.

- Make sure there is fuel in it when running

- Make sure the only thing in-front of your fuel pump is a pre filter, no check vales etc.

- Do not “Y” other things into your fuel system and check valve will only cause problems

- Make sure there is a VENT in your fuel tank or you will not be able to draw fuel out.

- When assembling new fuel lines run air then water through them to clean them out of any debris. All of our pumps are tested on our fuel pump bench for 20 minutes. They are particle free if you develop any scoring you have contamination

- Marketing video showing how to prime a fuel pump

- We recommend running between 3 – 4 bar of base pressure (43.5 – 60 psi)

- We recommend running between 45 – 60 psi of base pressure

- Belts rarely fail

- It can draw fuel itself but it up to you to provide a good source of fuel, of course running dry is not recommended.

- You should not under any circumstances use a check valve as most check valves cannot flow 10 gallons per minute this will starve the pump and your engine at high rpm

- Most commonly available regulators will bypass enough for our pump we have tested it.

There are a multitude of different options out there for choosing the right fuel system for your race car or high performance street car. Some go with a high flow electric pump, sometimes even two or three electric pumps, while others choose the route of a mechanical fuel pump. All are looking to achieve the same result – providing enough fuel for the motor. There is lot of benefits to both electrical and mechanical systems in a variety of forms of motorsports, but we’ll primarily focus on drag racing or street performance for this topic, although we have successfully used them in road racing to stop fuel overheating issues.

For most of you reading this, you’ve already gone through upgrading your in-tank pump or have gone to a larger external electrical pump, yet you’re still coming up short on fuel issues – once again. I say “once again” because you’ve been through this before with the progressive steps of chasing your tail to fuel your motors needs. Wouldn’t it be nice to get ahead of the game this time around and rid yourself of the headaches that come with running an electrical system?

You’re asking yourself, since my fuel system is all set up (with lines run and wiring done), it wouldn’t take too much to swap in a larger pump and carry on with tuning your car, or would it? The cost of pumps is minimal if not more for some electrical pumps. If larger lines and fittings are on the menu, definitely consider making the switch now. Plus it could save you from a lot of other issues to be concerned about as your power goals rise. Going the route of a mechanical fuel pump is straightforward, mounting the pump is probably the most intensive component of the switch. But now this is made even easier with kits available to drive the pump off the crank, distributor, camshaft or some accessory component. Running some new lines and fittings and you’re pretty much set up. All the electrical headaches of wiring and relays are a thing of the past. Seems too simple doesn’t it?

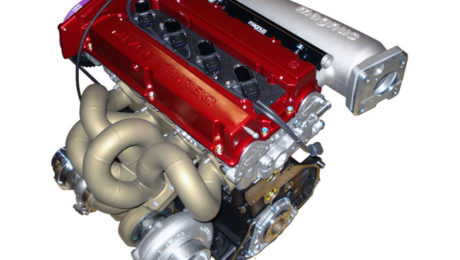

Yes, the mechanical pump setup is very simple with lots of benefits and few issues to be concerned about. The Magnus MF Pump can handle up to 9.7 GPM and support 2500HP on methanol to 5700HP on gasoline depending on the fuel type and base pressure. This should cover the majority of drag racing and street setups out there. For those that it doesn’t, stay tuned – we got you too! The following issues will be a thing of the past:

● You won’t be concerned with insane power draws from huge amperage pumps.

● It cannot mess with your ECU or tuneup no electronics needed to run it, no more fuel flow tapering because of to low battery voltage and pumps not keeping up.

● If you want to run 100 psi of boost, bring it on! This pump can handle it, does not drop pressure like electric pumps.

● Pump speed and flow tied to engine speed, there is no overheating of fuel.

There are safety advantages as well. If you are ever unlucky enough to hang your rods outside your block, the pump stops since it’s driven by motor speed. No one likes fueling an already dangerous engine fire. More fuel equipment is kept in the engine bay and in front of the firewall.

You do have to be concerned about the cleanliness of the fuel source. It likes super clean fuel, so running a nice prefilter is highly recommended in your setup if you don’t already have one. If you want to get that much more through, filtering the fuel before you put in the tank helps too. But other than that, you’re good to go.

There’s a bunch of stuff I could talk about the Magnus pump, but we’ll leave that for you to discover on its own product page. For now, you already have a ton of stuff to be concerned about on your race car, never mind the things you can’t control such as rule changes that may affect fuel types, turbo sizes, changes in turbo technologies. Let’s get the fuel pump equation out of the picture so you can focus on other things!

MAGNUS DRY SUMPS OIL SYSTEM

Magnus Dry Sumps continue to be sought after in every genre of Motorsports, including Performance Street, Drag Racing, Time Attack, Formula Drift and Rally cars.

Here at Magnus, we have been at the forefront of building race engines for the past two decades. When we say that we have done it all, we mean it, we have been through it all. Fortunately for the automotive enthusiast’s research and development being done by parts manufactures has been moving at such an unbelievable pace for the past decade and as engine and tire technology begin to reach new heights, the amount of G-force an engine experiences have increased dramatically. It has increased to the point where limitations to the factory engineered oil systems are being reached – a Dry Sump system has become a necessity.

High RPM launch control, Cornering, Launching, Braking, any one of these will upset the oil level in your car. In drag racing what we experience is 2 step launch control for 2 – 4 seconds (depleting the pan of oil) a multiple G-force launch, moving the oil to the back of the pan. High rpm runs in the 8500 – 11,000 RPM range, further deplete the pan of oil. Compound this with trying to drain back to the engine’s case while excess pressure from the rings try to push its way up to the valve cover.

Now, hit the brakes or pull the parachute! What little oil is left is pushed to the front of the motor. You can see why we resorted to overfilling our engines and immediately shutting them down after crossing the line. In road race applications it has helped tremendously in keeping oil pressure to the motor. Downhill sweepers where the OEM pump would have the problem of running dry. Overfilling the engines just would end up filling our breather tanks, causing other problems. All these problems together can cause the oil level in the pan to run below the oil pickup, causing the pump to run dry and destroy your engine, oil pump, or turbo.

MAGNUS DRY SUMP BREATHER CANS

Our breather cans significantly reduce positive pressure build up in the crank case, allowing your pistons to achieve higher RPM’s easier. Tanks include 3” filter and drain plug pre-installed, internal baffle, bolt in mounting bracket, -16AN female fittings that are meticulously Tig welded and hand spun from premium high strength, lightweight aluminum. Overall dimensions are 12″ x 3″ (including filter).

Consider Magnus anodized fittings for the best results – made in house at Magnus.

MAGNUS DRY SUMP GEARS AND DRIVES

Magnus Cam Gear HTD Drive Center MMCENG1018: Magnus Drive gear uses a HTD timing belt tooth profile to accommodate higher torque loads and is now integrated into the cam gear center section. Can also be used to drive other external components if necessary from the cam. Cam gears are universal and will fit Evo or DSM.

Magnus dry sump OIL PUMP PULLEYS are designed to give you optional shaft sizes (.500” and .625”), key gears sizes (.125” and .187”) ratios for your dry sump system to achieve that desired drive ratio. They are made from billet aluminum and feature a hard coat anodized finish for durability. Pulleys are available with several different tooth counts (32, 34, 36) to achieve the ratio that you need.

Magnus 14 Tooth Gilmer Gear MMCENG2150 : 1″ Bore .125″ Key, L-Series or HTD Profile

MAGNUS DRY SUMP BILLET OIL PANS

All Magnus Oil Pans are machined from Billet 6061 Aluminum, increase strength, lower center of gravity and reduce vibration. The design of the oil pan includes a low profile and internal baffles. Our 5 Axis CNC ensures industry leading precision and perfect seals.

Applications:

VR38 GTR RWD (MMCENG5051) : Dry sump pan is can be used alone or in conjunction with our RWD conversion kit, For clutch cars, TH400 equipped, anything but the factory trans. Designed to be able to remove the 4WD lower pan of the VR38 and lower the engine up to 5 inches. Lower crankshaft center line brings the VR38 engine to a more usable 8 – 9 inch crankshaft center line. Perfect for RWD tube Chassis cars, Street rods, Drift builds, Sports cars, and carbon monocoque vehicles that utilize the engine as a stressed member. 5 stage Peterson R4 Dry sump mounts are optional. Uses Factory GTR starter, factory GTR crank sensor, can be teamed with our billet flywheel and bell housing for 1 completely engineered combination. Will not work with factory oil pump, for use with Magnus Dry Sump components only.

2JZ-GE and 2JZ-GTE (MMCENG7000-005) : Magnus Motorsports Low Profile Billet Aluminum, one piece Dry Sump Oil Pan. Milled from 6061 Billet Aluminum, the rail thickness and added support structure promotes rigidity and durability, the total weight is 7.2 lbs. For use with 4 or 5 stage oil pump and a perfect match for the Magnus 2JZ Front Cover.

Subaru EJ20 / EJ25 (MMCENG2100-002) : Sump Pan with Integrated Mount is necessary for rally and high-performance applications. Our 100 percent billet dry sump pan is designed to mount our Dry sump pump directly to the pan. It also has a depression built in to allow Mounting of the Magnus MF fuel pump to the back of the Dry sump pump for those seeking tighter packaging.

4G63 (1G/2G/EVO) and RWD : The new updated version of our Dry sump pan features a 2-piece bolt together design which allows for disassembly and easy motor inspection. The sump portion of the pan can be configured to your specifications. This pan can be configured in RWD format or conventional transverse format. The Magnus dry sump oil pan will not work without the use of our Magnus 4G63 Billet front cover.

Honda K-Series RWD (MMCENG2200-001) : The Magnus K-Series K20, K24 RWD Dry sump is specifically made to work with our K series Billet block, but can also work on others. Features factory mounting locations and is adaptable to our R4 3 or 4 stage dry sump pumps. Adaptors and drives are also available to make this work in your RWD swap car.

MAGNUS PUMP MOUNTS AND OIL FILTER RELOCATORS

When altering your drive train, Magnus provides universal mounts to make the process more efficient. Popular conversions include FWD to RWD (K-Series Hondas), AWD to RWD (VR38 GTR). These billet mounts give you options like mounting, high or low on 4G63’s, or left and right on the Nissan R35 G-TR.

MAGNUS OIL TANKS

9 Litre / 2.3 Gallon External Dry Sump Oil Tank MMCENG2500 :

Magnus Hand Fabricated 7″ diameter 9Litre/2.3 Gallon universal tanks are designed for use in all engine applications.

Featuring:

Hand spun aluminum tanks are Precision tig welded on O ringed flanges which assemble at 30-degree angle to the flange surface allowing easy disassembly and assembly with simple hand tools. Internally baffled to aid in de-aeration of oil. -16 ORB fittings all around for large volume and flow. Will support 5 stages of scavenge venting and 30 gallon per minute oil pumps.

Brackets are included with all tanks, for secured mounting. Both top and bottom brackets have lightweight aluminum bases, stainless steel straps and sturdy rubber padding for added protection.

GT-R R35 MMCENG5000-201 : 9 Liter / 2.3 Gallon capacity DBA Dry Sump Tank (2012 – up)

Designed to fit behind the headlights of all 2012 and up GTR R35 with ample clearance.

For secured mounting, included in the kit are, top and bottom stainless-steel brackets in addition to the tank mount that features a lightweight aluminum base and stainless-steel straps with sturdy rubber padding for added protection.

7″ diameter 9Litre/2.3Gallon Tanks are designed for all types of racing. Fitted with a dipstick tube for GTR for measuring oil level. Featuring -16 ORB fittings all around for large volume and flow, hand spun aluminum tanks are internally baffled and vented and come apart easily for easy cleaning. O – ringed flanges with 5 axis machined Flanges put the assembly screws on a 30-degree angle to the flange surface allowing easy disassembly and assembly with simple hand tools.

DRY SUMP OIL PUMPS BY PETERSON

Our Dry Sump Kits feature the Peterson Fluid Systems Oil Pump. The pumps utilize a revolutionary twisted lobe rotor design with all aluminum rotors in all sections saving a huge amount of weight while also increasing performance. The internal scavenge manifold and shallow depth screw in fittings make for a low profile which equates to easy mounting. Finally, the pumps are modular, enabling 3 to 6 stages. Note: Stages refer to total number of pumping bodies which include (1) pressure section. i.e., a 4 stage pump includes (1) pressure section and (3) scavenge sections.

FITTINGS

Magnus fittings are made in house from 6061 aluminum and are anodized (in black) to provide scratch resistance. Their performance has been stress tested on track cars around the world and proven on World Record holders. They can be used for oil, gas, nitrous and to extreme temperatures. See our line of fittings that cover -AN, ORB, Plugs, Step Up and Step Down and “Y” fittings.

Aluminum Weld On Bungs Variants: Male: -8 Orb, -10 Orb, -12 Orb and Female: -20 Orb

DRY SUMP FEATURES

- Increased oil capacity (thanks to the remote reservoir) which allows the oil to cool and release entrained gasses from ring blow by and the action of the crankshaft

- Capability to mount the engine lower in the car. Goal: lower the center of gravity

- The external reservoir can be relocated to improve weight distribution

- Prevent oil starvation like seen in wet sump systems

- External oil pump allows for quick maintenance or replacement

- More horsepower

- Increased reliability

- The most consistent oil pressure is possible

- Reduced parasitic power loss

In this article we’ll highlight some of the differences between the newest generation 4G63 and the early 4G63 motors.

Here is one of our stage 3 Evolution engine blocks. This particular model is a stroker. We enlarged the bore to 3.366” and added 12mm more stroke to get roughly 2.3L of displacement.

Notice the proprietary Magnus pistons with the quench pad technology. These pistons are specifically designed for the Evolution engine, using experience we gained from working with the earlier 4G63 engines. The quench pad provides greater resistance to detonation and is basically an imprint of the head transferred to the piston. Why do we do this you ask? This helps squeeze all the gasses into a smaller space, making the combustion chamber smaller and more efficient.

Here is the Evolution 4G63 head, very similar to the old style head in casting but has a few major changes. First off we all know the flow is reversed. That won’t make any major changes to performance though. The injector bosses are now in the intake manifold instead of in the cylinder head. Placing the injectors a bit further back will give better atomization and also a bit more power. Although the 5 to 10 mm of distance that it has been moved to, to be able to get a measurable power gain would be splitting hairs… but it is an improvement nonetheless.

The intake ports have now been made a more normal size. The 1G port was always in our opinion too large to get good low end velocity out of. This head is much more of an improvement over the 1G DSM. The port entry angle is only 10 degrees; whereas the 2G DSM head had a much steeper entry angle, which was better for performance. A lot of manufacturers are getting away from steep angle intake ports which we can only guess for two reasons. A) Low hood line and less complexity for intake manifold castings or B) Emissions. Sharper angles will promote more tumbling and better atomization, aiding in emissions controls.

This picture shows finished intake ports displaying the 10 degree entry angle.

Here we see a finished Evo port up against a 1G DSM intake manifold flange for comparison. That’s a huge difference!

Here’s a finished EVO port and how it matches up against our CNC machined intake manifold flange. This image also visually shows the injector bosses.

The exhaust port is almost identical to the original 4G63 engine. Very little has changed except the bolt pattern which didn’t even change that much, its just reversed.

Here we take the Stage 3 Head and sit it down on the Stage 3 block. Now comes the task of checking clearances and degreeing the camshafts. We wanted this motor to run a 9:1 compression ratio so we opted for a .030″ gasket. Had we wanted to try 8.5:1 compression ratio, we would have installed our .060″ gasket.

After the piston clearances have been checked (our pistons allow high lift cams to be used without interference problems) we dry assemble the Timing belt pulleys and idlers temporarily so we can make degree in the cams, making sure they are installed at the manufacturers specs. This not only ensures that the engine will run properly and make power where it is supposed to, but it also ensures that you won’t have any clearance issues between the valves and pistons if your block and head have been decked a few times.

Now that we are sure the camshafts are degreed and installed correctly, we checked for valve clearance and it was more than adequate. Now it’s time to begin buttoning up the motor. The timing belt pulley are removed and the gasket is installed on the oil pump housing. The air separator baffle is installed (Very important do not omit this item, this prevents the oil pump from picking up air bubbles instead of straight oil) along with the oil pick up tube. We use a light coat of sealant on both sides of the front cover gasket, but always install the pickup gasket dry, so as not allow any sealant to get into the oil pump where it could instantly destroy the motor.

The oil pan is installed and the rest of the timing belt accessories are put back on for good this time, including the crank sensor. Notice our custom balance shaft eliminator plug. They are machined from 6061 aluminum in house. We use this instead of the Mitsubishi rubber plug because the rubber plug has a tendency to fall out and cause a gargantuan oil leak… at the most inopportune moments. Now that we no longer have balance shafts installed, this means the oil pump orientation when setting the belt is no longer critical. What’s different on the new 4G63 is the timing markings. You must have the rocker cover on to set the timing belt. Why? Because the rocker cover has the cam gear timing marks on it.

There it is all installed, belt on and ready to go, but wait there’s something missing.

There’s the Magnus EV0 8 stage 3 2.3 Stroker Motor with a sexy Intake Manifold attached to it. Now it’s ready to go with.. extra torque and horsepower!

Magnus motorsports is the leading 4G63 engine builder in the world. Our engines have won a considerable number of world championship races in numerous motorsports arenas, including Drag Racing, Road racing, Autocross, Rally and Hill climb.

Our 13 years of experience have allowed us to create multiple variations and combinations for the 4G63 which give the driver the ability to completely tailor their powerplant to the type of racing required.

We have invested a great deal in research and development to produce prototypes and race these new combinations for the 4G63. We have perfected each of our designs to create maximum power and the ultimate in reliability allowing us to provide this product to the enthusiasts and racers alike.

As innovators within the Mitsubishi community, Magnus Motorsports has built and tested high compression turbo motors, 2.4L Long rod, 2.1L 2.2L Long rod and Methanol burning 4G63s at 90 psi of boost long before these ideas have been adopted by the rest of the Mitsubishi world. No other engine supplier in the world has researched as extensively as Magnus Motorsports nor do they offer as many components for the 4G63 and its variants as we do. We have designed, tested and run over 150 different piston designs and variations in the last 10 years alone with compression ratios from 7.5:1 all the way to 15:1

We have always strived for more performance with reliability in order to stay ahead of the competition. Our advances in 4G63 technology have put us miles above the rest simply because we refuse to rest on our laurels and allow our competition to catch up. The fastest Mitsubishis in the world run Magnus components for a reason, they win races and they never give up first place.

Previously, this “private stock” of components was reserved only to our own cars and engine builds. Due to demand by several customers requesting these components be released for public consumption we have decided to declassify our highest technology components and offer them for sale.

Over the past four years, we have taken these engines to over 1400 HP, 11 000 RPM+ and 90+ PSI of boost pressure. These are demands that were never thought to be possible with this platform, but Magnus has made these a reality. These are the parts we use in the worlds fastest Mitsubishi race motors and can be used in yours. We have put together a detailed guide that will outline what components you will need to build yourself an engine of this caliber. This guide will give you a general idea as to identifying the best combination for your specific application. Keep in mind that we can build complete engines to your exacting requirements should you be after a “turn key” solution.

All of our pistons included in this stroker kit utilize the Magnus Quench Pad Dish design which mirrors the quench pads on the 4G63 cylinder head, This gives our pistons extremely high detonation thresholds. All of our pistons have enough valve pocket to clear 12.5mm lift cams. They feature a unique new shape to help quiet the forged piston noise usually associated with running loose tolerances, .0055” + piston to wall clearance is the absolute minimum needed to survive at elevated horsepower levels. Advanced ring packages are included on all of our pistons for superb break in and excellent sealing.

Magnus rods have an advanced profile and are built to withstand the torments of high hp and high RPM. Our Alloy rods feature L19 fasteners to allow for more clamp loading on the rod to survive at high RPM. They have been tested at over 350hp per cylinder. We recommend that any engine running over 800 HP should use our Aluminum Rods with our 23MM pin upgrade.

Magnus Crankshafts are machined from a solid piece of 4130. Our cranks have lightening hole knife-edged counterweights , large radius fillets and cross oil drilling. They start life as a 200kg chunk of steel and are machined and prepared to our exacting tolerances, they are then Nitrated and finish ground to exact tolerances. Finally they are precision balanced and are ready to install. No further machining or “corrections” are necessary as with other crankshafts on the market.

The quality of these pieces are second to none and come together in this stroker kit to provide the performance and reliability that Magnus customers have come to expect. By releasing this kit into the marketplace, Magnus has once again raised the standard that our competition strives to reach. If you are a driver looking for the ultimate competitive advantage, Magnus Motorsports just made it happen.

We have seen even stock EVO X’s under spirited driving blow up the master cylinder, our latest design addresses this issue. This DIY guide will help you get it done right.

evox_gsr_clutch_master_cyl_install_guide (view file for pictures or print)

Tools needed;

10mm, 12mm, 13mm, 14mm end wrenches and sockets

12mm deep well socket & 3” extension

Vice grips or channel locks (Tongue & groove plier)

Various common screw drivers

Needle nose pliers (Curved end preferred)

End grinder with burr bit or small angle grinder or Dremel with cut off wheel

Below is a burr bit on an end grinder, this is what I used and preferred but please wear safety glasses when grinding

or cutting. This is a cold style of cutting so no sparks to cause fires like other grinding methods. This can be used on

an air or electric end grinder and cost about $30 for a good sharp on that will last quite some time.

The only material needed is some DOT 3 or 4 brake fluid to refill your reservoir’s when you’re done.

Before we get started on the master cylinder we need to clear a few items out of the way to make life easier and

less frustrating. I won’t go into detail on the basics just an overview.

1. Read all the way through this install guide before beginning.

2. Verify you have all the right parts

3. Disconnect the positive battery terminal

4. Remove the strut bar

5. Remove air intake back to turbo

6. Remove positive distribution block and ECU (Including brackets)

7. Remove boost solenoids and vacuum lines

You should have everything that’s in the picture below; (Plus DOT 3 or 4 brake fluid)

Now with those items out of the way we can start on removing your existing clutch lines. Below is your slave cylinder

remove them 12mm bolt holding the stainless hard line on and start pulling the line back to the firewall.

When you get to one of these clips pull firmly with vise grips or channel locks, then pull the line to you and up to remove

line from bracket.

This little gem is your brake booster and brake master cylinder, and it has to be removed.

First pull the harness off and tuck it out of the way.

Now remove the hardline using a 12mm end wrench, you will have to get these pulled out of the way later.

Now unbolt the brake master cylinder

Remove the hose off the reservoir

Pull and remove! Keep in mind brake fluid eats paint so any drips wipe off ASAP.

Here is what your left with, its now time to move inside the car and get down with the pedals.

On the brake pedal you have to remove this pin that holds the brake booster fork.

Now remove these four 12mm bolts

Those bolts just freed up the brake booster to be pulled (Remember to be careful not to bend the hard lines too much)

Now since your still under the dash before you pull the boost reach over and unhook your MC’s arm it just pushes off.

With the big booster out and arm for the MC unhooked grab its body and twist / pull it out.

Now that there are two gaping holes in your firewall let’s do some grinding! See the nubs grind them off it’s that simple

they are holding studs you need out of the way.

What finished looks like

Time to bolt it down now and you may need a second person to hold back up for you

Notice the orientation in the picture above and be sure you orientation is correct it’s a tight fit

Now that the brake booster is back on its time to go put its 4 bolts and pin back in as well as get the MC arm secured to

the clutch pedal. You know that weird little “L” shaped piece; here’s what it’s for. Slide it over the ball and cinch it down.

A little better view or orientation and part fitment to keep in mind when installing.

Now route the braided line back to the slave cylinder mounted on the transmission and install the banjo fitting.

Now you should be ready to bleed the system, I suggest using a vacuum bleeder to ensure you have it done correctly.

You want to bleed from the slave cylinder on the transmission; it has a bleeder nipple on the top side of it.

Loosen the bleeder and pump the clutch a few times then hold. Add fluid to the reservoir as needed and repeat until

clutch is firm and actuating the slave as designed. If by chance the slave gets stuck use a screw driver to pry it back.

Once you have that bled of its time to move onto the brakes since you depleted that reservoir as well. Start with the

farthest brakes and work your way forward. Passenger side rear – driver side rear – passenger side front – driver side

front. Repeat until your brakes don’t feel spongy.

As always double check everything before going for a test run and feedback is always appreciated.

Hollywood_X

Parts can be found at;

http://magnusmotorsports.com/

EVO X Clutch Master Cylinder Upgrade Kit

Magnus went through extensive testing to develop the Evo X Clutch Master Cylinder Upgrade kit (CMC) in 2010 for LHD and RHD. BEWARE other companies that have duplicated this product with inferior parts. Magnus has the best components and is designed to outlast your car. The problem is the original plastic clutch master cylinder on the Mitsubishi Evo X was not engineered to handle the increased pressure exerted by higher strength racing clutches. The original which is made of plastic, can break when under normal use or even more so when combined with with an aftermarket clutch eventually splits leaving you stranded without a clutch.

Product Description

The originator and rated best in design and performance the Magnus CMC Clutch Master Cylinder Upgrade kit, replaces the OEM clutch master cylinder in a Mitsubishi Evo X GSR with a stronger more reliable setup, allowing you to upgrade to a stronger clutch while eliminating the possibility of failure. This kit is designed to adapt the clutch master cylinder out of the Evo VIII & Evo IX into the Evo X. The thick T6061 aluminum construction eliminates any deflection from the heaviest of racing clutches. It’s solid, single surface design dissolves any fatigue points giving the setup a longevity over any other kit on the market. One benefit from this assembly is the innovative pedal joint assembly found only on the Magnus kit. This hard anodized billet aluminum design eliminates the need to cut off the original pedal ball joint to accommodate a heim joint. It also provides you with the ability to adjust pedal height with ease while safely locking the assembly in seconds. Anybody who has been on their back trying to work on their pedal assembly under a dash will appreciate how easy this makes the entire process. All you do is break the jam nut screw remove the clip, pull off the ball-joint and thread to your desired clutch pedal height. The elegance of this design is that it allows you to test the height rather quickly without committing to tightening the locking clip until you are ready. Change the height, test the pedal and adjust some more. This is the easiest, most convenient, and more accurate way to control the height of your pedal. Included in the kit is a one piece braided stainless steel clutch line that upgrades and completely replaces the factory clutch line in the car. You can order the Mitsubishi OEM master cylinder through us choose to order it through your local dealer to expedite delivery times. If you intend to order the master cylinder yourself, do not replace it with a re-manufactured or aftermarket master cylinder. We did a year of testing on the various products to find that only the OEM factory Mitsubishi Part MR491945 holds up over time. This kit is configured in a right hand or left hand drive option to accommodate our worldwide client base. Please specify if you need a right hand drive configuration in the choices before checkout, or contact us. If you do not specify, we ship the left hand drive setup.

AVAILABLE WITH OR WITHOUT MASTER CYLINDER WE SUGGEST YOU PURCHASE THE OEM MASTER CYLINDER FROM US IT IS AVAILABLE IN THE DROP DOWN. OTHER SCUMBAG SHOPS (MAP PERFORMANCE) SELL A KNOCK OFF VERSION OF THIS KIT WITH TERRIBLE QUALITY PARTS BUY THE ORIGINAL FROM US AND DON’T BE LEFT STRANDED ON THE ROAD.

Features

- T6061 aluminum black anodized adapter plate with dual surface design.

- Innovative quick adjustment connector to change your pedal height.

- Hard Anodized ball joint with stainless steel retaining clip

- Zero gasket / high tolerance design eliminates points of failure or the need to replace gaskets that will fail long before this kit will.

- Includes a full one piece stainless braided clutch line.

Options

- Right or Left hand configurations available.

- With or without an OEM Evo VIII/IX master cylinder supplied, if you want to source your own.

Applications

- Mitsubishi Evolution X GSR LHD

- Mitsubishi Evolution X GSR RHD

Part #

- MMCDRV1002 – CMC kit with master cylinder included Left Hand Drive

- MMCDRV1003 – CMC kit with master cylinder included Right Hand Drive

- MMCDRV1005LH – CMC kit NO master Left Hand Drive

- MMCDRV1005RH – CMC kit NO master Right hand Drive

Magnus Detailed Engine List

• All pistons are available in any custom bore size and custom compression ratio’s

• Headgaskets available are up to 87mm larger bore sizes must source own gasket

• We recommend steel rods for anything up to 800HP

• Anything above 800 hp we recommend aluminum rods and our 23mm Pin upgrade

• Anything running above 9500 RPM must use our valve springs

Magnus Motorsports Evo VII-IX CT9A Front Subframe

As the Mitsubishi Evolution CT9A platform continues to get faster and faster, we are all demanding more from the chassis. As the level continues to reach a new peak, we continue to create new products to solve known & arising problems that come with making more power, increased G forces and huge gains in overall speed.

We revised our original subframe design to make it stronger and more suited to all forms of motorsport and street cars.

The DSM Shootout has definitely outgrown the little “Drunk’N’Drag” get together for some DSM enthusiasts that was fulfilled with some sweet 12second cars and drunken stories. It really puts a smile on our face to see that The Shootout has grown to an almost 10,000 attendee event. Yet another great shootout has gone by and the race to next year’s event has begun. Seeing this year’s achievements for both driver’s and event attendance has left us with nothing but an imagination of how great next year’s Shootout will be.

We had decided to approach this year’s shootout quiet differently, the usual let’s slap the motor together, tune the car and throw it in the trailer approach was thrown aside. We had chosen to build some wondering and confusion for those attending by doing something never done before, and posting teasers of our car on the “interwebs”. Marco had come up with a crazy idea of doing a Cantilever set up in the rear end that had even the employee’s scratching their heads. Before we knew it we were cutting up the suspension and looking for a way for this to work. Therefore the shootout was more of a test and tune for us than a racing competition.

Our reason for leaving the traditional rear end set all started with a simple decision to upgrade to a 3000GT rear end…… Well simple was clearly an understatement, the new objective was to add a bigger tire and run a true drag shock. Our goal wasn’t to fab everything up and throw it in the car for some street cred. The objective was to improve traction and make the car go straight.

We could not be any more satisfied with the outcome of the cantilever set up we had come up with here at the Magnus Minion Headquarters! Everything went as planned and the car did exactly what we had intended on.

Our good friend Gary Andr brought out his RWD 1G build and broke quiet a few necks with it. Although the car was not race ready, it was one hell of a teaser for everyone of what’s to come!

We would also like to congratulate our friend Mike with trapping at 158mph at the shootout , and most importantly thank him for all his help and support year round. We would also like to thank our friends John Wigger, Gary Andr, Nathan Samuels from Apex Motoring, & Mike Andolsun for all their help throughout the weekend!

- 1

- 2